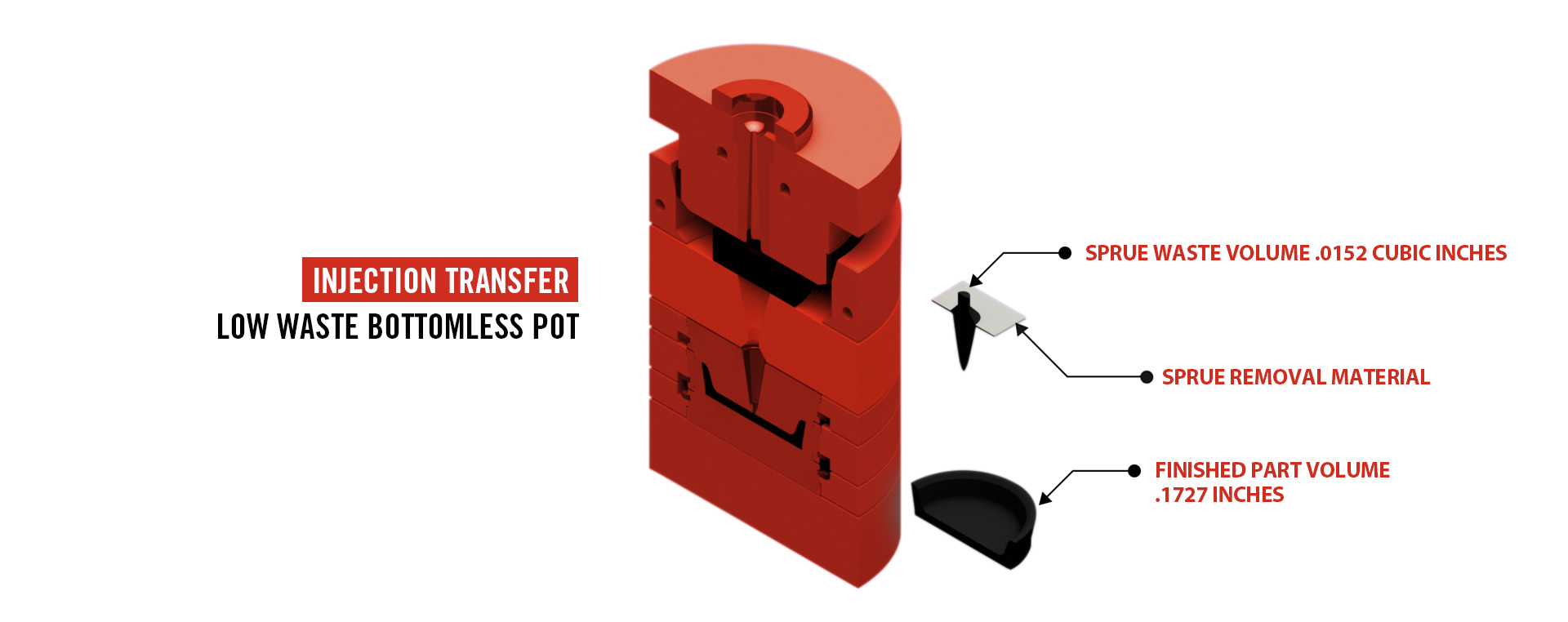

With injection transfer molding, the rubber prep is injected into an open pot and then pushed into the mold cavity. The pot can be hot, cold (low waste), integral or bottomless. The press used is an injection press. Flash control is trimless/flashless (ground lands) or tear-trim. With this process a high volume of parts can be produced quickly. Mold construction can be inserted or cut in plate.