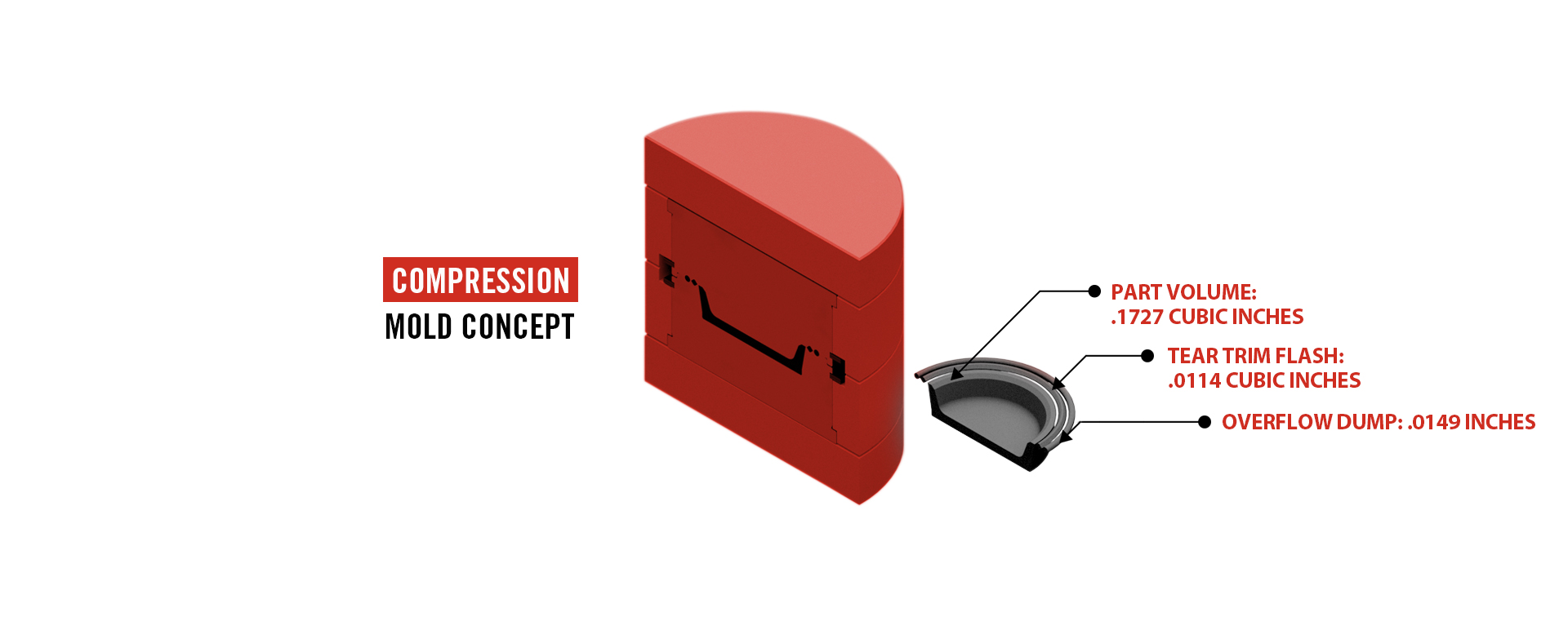

In compression molding, the rubber prep is loaded into the mold cavity, then the cavity is compressed in a compression press to fully cure the rubber material. The part is then removed by the operator. Flash control is tear-trims and overflows. Tear-trims and overflows can be removed by the operator or a secondary deflashing operation. This mold process is easy to operate and cost effective. Mold construction can be inserted or cut in plate.